India has struck gold.

The world’s fifth-largest economy and possibly now most populous country discovered one of the biggest lithium deposits globally.

That could be a game-changer for the country and help boost its manufacturing sector, as the metal is heavily relied on in the use of batteries for smartphones and electric cars among other items.

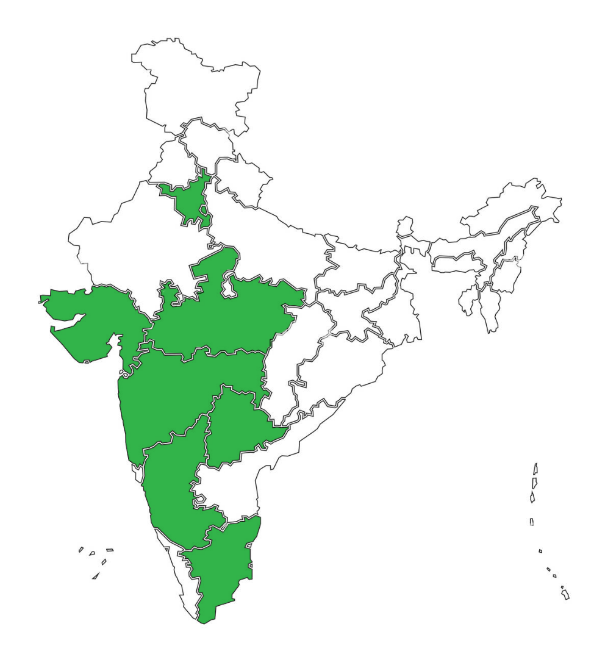

India has 20 lithium mining exploration projects nationwide and the Geological Survey of India confirmed the discovery of a 5.9-million-tonne reserve of the alkaline metal in the north of the country.

There are hopes that the find could accelerate the country’s transition to electric vehicles (EVs).

While the potential is great, industry insiders and analysts have welcomed the news with a measured response.

They say it will be years before the lithium enters widespread commercial use and helps to reduce India’s reliance on imports.

There are a range of challenges to overcome that include the complexity of mining, environmental concerns and the requirement for billions of dollars of investment.

The discovery of the lithium “will take us a step forward on our journey of achieving India’s EV target of 2030”, says Pankaj Sharma, the co-founder and director at Log9 Materials, a Bengaluru-based nano-technology, which makes battery packs for EVs.

India aims to have EVs account for 30 per cent of car sales by 2030, as it strives to cut its carbon emissions and dependence on crude oil imports.

“It might take a few years to mine the lithium before it reaches the industry for EV battery production,” Mr Sharma says.

He cites hurdles include the millions of litres of water needed to mine the metal, while a large amount of carbon dioxide is released into the atmosphere in the process.

“The utilisation of the mined lithium to make EV batteries also involves a lot of challenges — converting it to battery-grade lithium and sourcing other EV components and materials, such as cobalt, nickel, required to produce high-quality lithium-ion batteries,” he says.

India has been heavily dependent on imported lithium-ion batteries because of a lack of raw materials to make the cells.

This means it imports about 70 per cent of its battery-cell requirements from China and Hong Kong, according to the consultancy Arthur D Little.

These costs add to India’s trade deficit and to the cost of manufacturing EVs and various products that require lithium-ion batteries.

It is crucial for India to produce cells domestically as demand grows and the country will need to invest more than $10 billion into cell manufacturing by 2030 to meet its needs, the consultancy estimates.

Once the metal is extracted and comes into use, the country may accelerate “production and adoption of clean and green mobility”, given India’s rising demand for lithium and lithium-ion cells and batteries, says Ashutosh Verma, the founder of green energy startup Exalta.

The lithium discovery is also a positive development that can help reduce India’s dependence on imports in tandem with government efforts to grow the country’s manufacturing sector and create jobs.

To encourage battery-cell manufacturing, India’s government has been offering incentives under India’s $2.2 billion advanced chemistry-cell scheme.

“The availability of domestic lithium reserves could lower costs, increase the competence of EVs in the domestic market and support the government’s goal of increasing EV adoption,” says Aditya Vikram, the co-founder of Renon India, a lithium-ion battery storage company based in Gujarat.

But the development and commercialisation of the lithium reserves will require significant investment in mining and processing infrastructure, he says.

Mr Vikram is hopeful that India’s lithium can help his company to manufacture lithium-ion batteries “with enhanced efficiency” and more cost-effectively.

The lithium discovery “could be a game-changer for the electric vehicle industry”, says Manvinder Singh Chugh, the founder and chairman of Aponyx Electric Vehicles.

“The EV industry in India has been held back by a lack of reliable local lithium supply.”

Kalyan C Korimerla, the managing director and co-promoter at Hyderabad-based EV manufacturer Etrio Automobiles, says things are still at an early stage when it comes to lithium production in India, and there is a need “to ascertain the commercial viability … and investments in lithium batteries need to be prioritised” before the industry can benefit from the find.

Experts say it is hard to predict when India’s lithium might be available in the market.

“It’s critical to ensure that lithium mining is done responsibly and sustainably to avoid damaging the environment, particularly soil and water pollution,” says Barnik Maitra, the managing partner at Arthur D Little, India.

:quality(70)/cloudfront-eu-central-1.images.arcpublishing.com/thenational/PJLHF2NUMVJUFCN7K546WCCKVY.jpg)

He also points out that the population of the local village, numbering in the thousands, would have to be displaced and provided with new homes elsewhere.

Major projects in India are sometimes met with opposition from residents.

The deposits are expected to be auctioned off for private companies to mine.

Mining lithium is a complicated process that requires specialised technology and expertise, which will require India to team up with global companies.

“India will continue to depend on imports for next few years,” says Mr Maitra.

The process “will depend on multiple factors including government approvals, bidding process for mining, interest from industry, technology acquisition, concentration of deposit, geological factors, setting up of refining infrastructure”.

He estimates that the quantity of lithium that India has identified would be plentiful to meet the country’s domestic demand while also exporting the metal.

Refining is the “most critical step and it will need large investment”, Mr Maitra says.

Currently, China is a leader in lithium supplies because it has invested heavily in its refining capabilities and acquisition of mines around the world, as well as having its own lithium reserves.

Bolivia has the world’s largest lithium reserves, with more than 21 million tonnes, but because of a lack of investment in infrastructure, the South American country is not a major producer.

Australia, Chile and China are among the largest producers of lithium. India’s 5.9 million tonnes of reserves places it firmly in the top 10 producers.

:quality(70)/cloudfront-eu-central-1.images.arcpublishing.com/thenational/HG2TYOCIQVDMHECT7DZB4FSN7E.png)

But having large reserves does not necessarily mean that all of it will be suitable for use in batteries, experts say.

India will require further studies to reach the final category of ‘mineable reserves’, where the ministry of mines can determine exactly how much tonnage of the metal is available, how much can be extracted and the quality of the mineral, says Anand Kabra, the vice chairman and managing director of Kabra Extrusiontechnik, an Indian manufacturer which recently ventured into making lithium-ion battery packs under its Battrixx division.

“On an optimistic note, it may take at least five to seven years to commercially exploit this metal,” he says.

“The country will slowly become self-reliant if more such deposits are found in future.”

Pravaig, a Bengaluru-based manufacturer of EVs, makes its own batteries.

Its co-founder Ram Divedi says the lengthy process for production of lithium gives India time to step up its cell-manufacturing industry first.

“India barely manufactures cells today but investments are being made by private companies with the help of a first batch of [the government’s] production-linked incentive,” he says.

“So, it’s very good timing — when the cell-manufacturing capacity of India will be ready, the country will have access to abundant lithium.”

Source: The National News

Published On: February 20, 2023